Mould Actuation System

The DFS Mould Actuation System is a hydraulic machine used for actuating large mould tools such as those used in producing the shell assembly for wind turbine rotor blades. The system enables the lifting, rotating, and clamping of the blade moulds necessary for the wind blade assembly process.

Hinges

Hinges are actuated by hydraulic cylinders each with a torque of 450kNm, enabling a full and smooth 180-degree rotation of the mould.

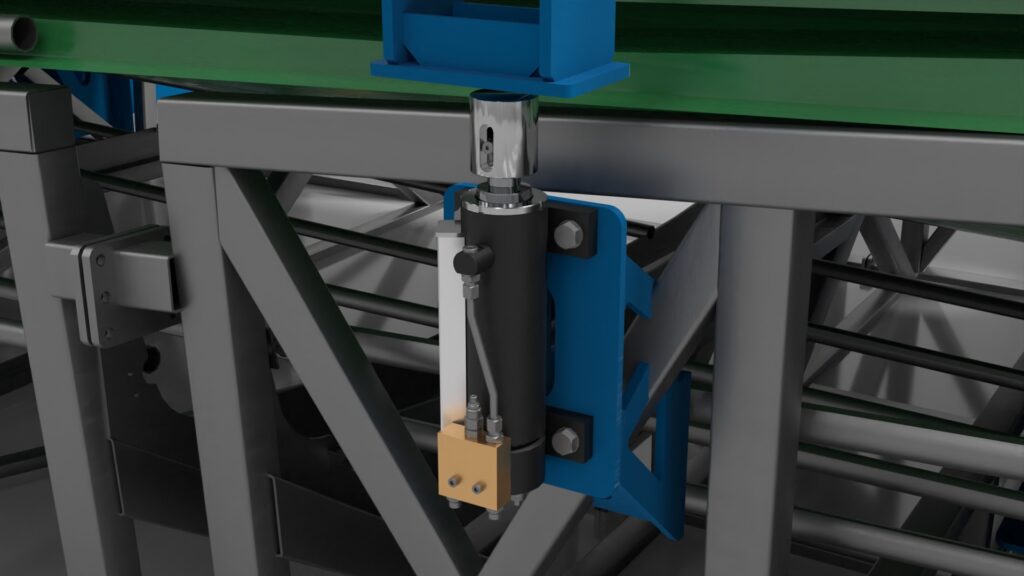

Jacks

Hydraulic jacks located at Leading Edge, Trailing Edge and Inside Hinge each with a lifting capacity of 19.5 tonnes that enable 150mm vertical travel of the mould.

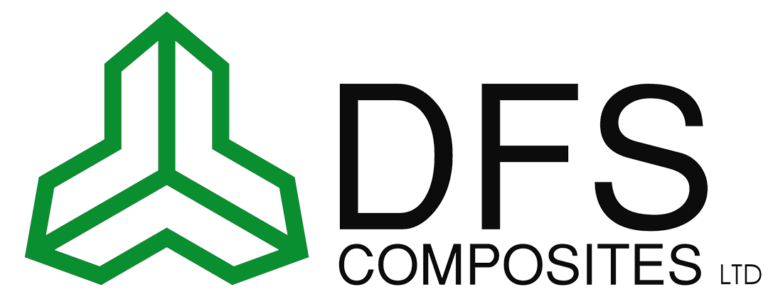

Clamps

Hydraulic clamps allow the compression of the bonding paste during the rotor blade assembly process when the mould is fully closed. The Clamping Process also allows for alignment between the PS and SS mould halves.

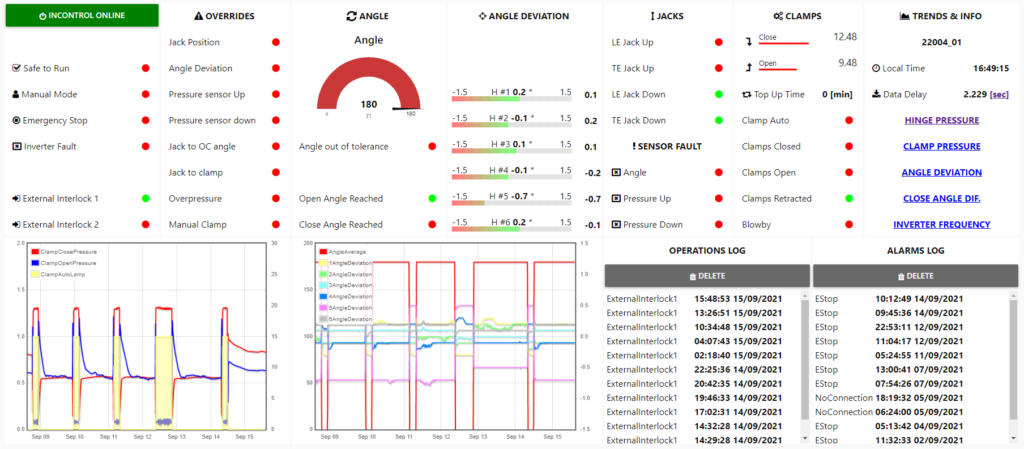

SCADA

Our internal SCADA monitoring system allows for active monitoring of all of our Mould Actuation Systems around the world. This enables our global service team to assist with service calls with ease, providing them with all the information they require for assisting our customers.

The system is also capable of displaying historic data which allows for in-depth root cause analysis and full operational history tracking.

DFS

Our mission is to deliver turn key tooling solutions for the wind industry including mould turning systems, blade assembly systems and heating solutions.

Solutions

Contact us

- Phone

- +44 (0) 1329 760397

- info@dfscomposites.com

- Facility and Office

- DFS Composites Ltd

- Unit 15, Spitfire Way

- Faraday Business Park

- Lee-on-the-Solent, PO13 9GW

- United Kingdom

© 2021 DFS COMPOSITES ALL RIGHTS RESERVED

© 2021 DFS COMPOSITES ALL RIGHTS RESERVED